Compare 3 Different SCM Moulders

SCM molders are equipped with multiple cutter heads and spindles that rotate at high speeds to cut, shape, and profile wood according to specific designs and dimensions. These machines can handle various types of wood, including hardwoods, softwoods, and engineered wood products.

Looking to select the right moulder for your shop? See some of the key differences between models below:

SCM Class tf 130ps

Key features:

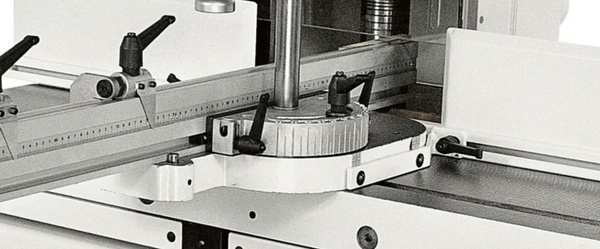

Integrated front sliding carriage. By incorporating a front sliding carriage into the table, along with a tilting telescopic fence and a protective hood featuring a dedicated armguard, operators can conveniently and securely perform tenoning and profiling tasks with ease.

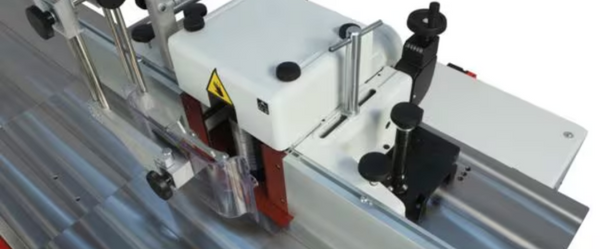

Enhanced efficiency and user-friendly operation. This is achieved with the Spindle moulder fence featuring mechanical programming. With maximum setup speed and simplicity, there's no need for trial runs, as digital readouts guarantee precise positioning of the two worktables to within a tenth of a millimeter.

Enhanced efficiency and user-friendly operation. This is achieved with the Spindle moulder fence featuring mechanical programming. With maximum setup speed and simplicity, there's no need for trial runs, as digital readouts guarantee precise positioning of the two worktables to within a tenth of a millimeter.

SCM Minimax tw 45c

Key features:

Technical Data:

|

Minimax tw 45c |

|

|

|

Max. useful spindle length |

mm | 100 |

|

Spindle moulder speed (at 50 Hz) |

giri / min | 3500 / 7000 / 10.000 |

|

Max. tool diameter when profiling |

mm | 210 |

| Max. tool diameter lowered under the table at 90° | mm | 180 |

| Max. tool diameter when tenoning | mm | 275 |

| Three-phase motor starting from | kW/Hz | 5 (6) / 50 (60) |

SCM Nova tf 110

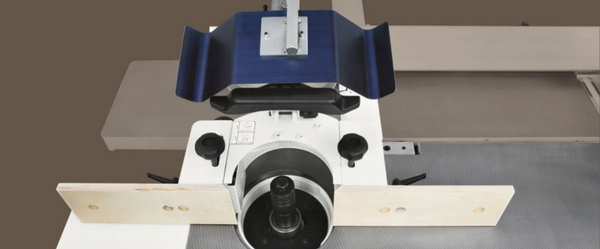

Key features:

Technical Data:

|

Nova tf 110 |

|

|

|

Max. useful spindle length |

mm / inches | 140 / 5.5 |

|

Spindle speed (at 50 Hz) |

rpm | 3000 / 4500 / 6000 / 7000 / 10000 |

|

Max. tool diameter of the profiling tool |

mm / inches | 250 / 9.8 |

| Max. tool diameter retractable under the table at 90° | mm / inches | 320 / 12.6 |

| Max. diameter of the tenoning tool with spindle diameter 30-35 (40-50) | mm / inches | 300 / 11.8 |

| Three-phase motor | Hp | 10 |

Mechanical programming. The spindle moulder fence features mechanical programming for maximum setup speed and user-friendliness. Eliminate the need for test runs with digital readouts, guaranteeing accuracy to within a tenth of a millimeter when positioning the two worktables.

Mechanical programming. The spindle moulder fence features mechanical programming for maximum setup speed and user-friendliness. Eliminate the need for test runs with digital readouts, guaranteeing accuracy to within a tenth of a millimeter when positioning the two worktables.